Progress in Research on Magnetic Flux Leakage Data Processing and Defect Identification Quantification Methods

-

摘要:

漏磁法是最稳定的无损在线检测技术之一,用于评估油气管道的健康状况。从通道基线校正、异常值判别、数据缺口的恢复和滤波四个方面阐述了漏磁数据预处理的方法和步骤;结合漏磁数据缺陷的峰谷值等显性特征,总结了不同特征提取方法下缺陷信号的本质特征;介绍了基于支持向量机、神经网络、图像处理和形态学等方法构建缺陷反演模型。最后,从数据预处理和缺陷识别量化两方面展望了漏磁信号处理未来的研究方向。

Abstract:Magnetic flux leakage (MFL) method is one of the most stable nondestructive on-line testing techniques used to assess the health of oil and gas pipelines. The methods and steps of MFL data pre-processing are described from four aspects: channel baseline correction, outlier discrimination, data gap recovery and filtering. According to the dominant characteristics such as the peak-valley value of the defect in MFL data, the essential characteristics of the defect signal under different feature extraction methods are summarized. The defect inversion models based on support vector machine, neural network, image processing and morphology are introduced. Finally, the future research directions of MFL signal processing was prospected from two aspects: data pre-processing and defect identification quantification.

-

石油和天然气是世界上最重要的“一次能源”来源。鉴于石油和天然气的流动性,管道运输在石油和天然气运输方面具有无与伦比的优势[1]。随着管道服役时间的增加,管壁上的缺陷可能会导致石油和天然气泄漏,造成巨大的经济损失,环境污染,甚至人员伤亡[2]。因此,准确评估管道的结构完整性和可靠性对于石油和天然气运输以及生命财产安全都极为重要[3-4]。漏磁(MFL)内检测是一种无损检测管道内部缺陷的技术,永磁体具有体积小和质量轻的优势,被广泛用于漏磁内检测器中[5]。漏磁内检测技术具有环境要求不高、适用范围广、价格低廉等优点[6-8],是目前应用最广泛、最成熟的技术[6-9]。

在漏磁内检测技术中,磁化强度的确定将直接影响管道检测信号的灵敏度和磁场的准确度。当磁化强度接近饱和或饱和时,检测灵敏度高,检测信号明显,便于漏磁场的检测[10]。利用麦克斯韦方程组,研究人员提出了各种描述泄漏磁场的方法,包括有限元模拟和磁偶极子模型分析[11-13]。检测到漏磁信号后,通过分析和识别缺陷[14-15]可进一步了解相应的缺陷类型和大小[16]。典型的信号识别通常涉及磁偶极子模型分析和算法优化[17-19]。随着石油和天然气管道里程的增加,内检测器装置采集到的漏磁信号质量逐步降低,对后续数据分析工作造成阻碍。漏磁数据分析主要由四部分组成:数据预处理、缺陷识别、缺陷量化以及管道安全评估[20-21]。管道漏磁检测的数据量巨大,通常150 km管道会产生约100 GB的数据[22]。计算机可以实现高速率采样和处理漏磁信号。手动筛选检测数据方法效率极低,并且正逐渐被管道检测自动化所取代。因此,亟需找到一种可行有效的漏磁数据缺陷识别量化技术,从根本上提高漏磁数据预处理和缺陷识别量化精度。

1. 漏磁数据预处理

数据预处理分为通道基线校正,异常值判别,数据缺口恢复和滤波四个部分[23]。

1.1 通道基值校正

通道是由传感器、机械支架组件、与数据采集系统电气连接并用于采集漏磁数据的电子设备(抗混叠滤波器和模数转换器,ADC)组成的系统[24]。

漏磁传感器有两个自由度:轴向移动和倾斜。这两者加上传感器跳动引起的噪声、量化误差等都可以看作是系统的状态。每个传感器通道的动态行为由系统状态在状态空间中移动的方式决定。假设每个状态独立反映在输出中,则认为本系统是可观察的。对于一个可观测系统,每个状态都有对应的输出

,因此可以对其进行校正[25]。系统状态的计算如式(1)所示。

,因此可以对其进行校正[25]。系统状态的计算如式(1)所示。

(1) 式中:M(T,t)是由

(λ,t)CT(λ)ϕ(λ,t)dλ给出的可观察性Gramman矩阵;向量x(t)表示时变系统的状态;Ф表示状态转移矩阵;C表示测量矩阵。

(λ,t)CT(λ)ϕ(λ,t)dλ给出的可观察性Gramman矩阵;向量x(t)表示时变系统的状态;Ф表示状态转移矩阵;C表示测量矩阵。

如果可观察性Gramman矩阵是非奇异的,则可以找到其初始状态在给定区间[t,T]上

(t)积分的值,从而确定通道的均值,然后利用通道均值数据完成一次校准。

(t)积分的值,从而确定通道的均值,然后利用通道均值数据完成一次校准。

1.2 异常值判别

测量人员的主观原因、外部条件和仪器的影响可能会使个体数据与样本数据发生偏差[26]。如果个别数据与样本的其他数据存在显著偏差,则怀疑其为粗误差,包含粗误差的测量数据称为异常值[27]。数学模型中判别异常值的常用方法包括t准则、Dixon准则、Schwyzer准则、3s准则、阈值分割等[28]。

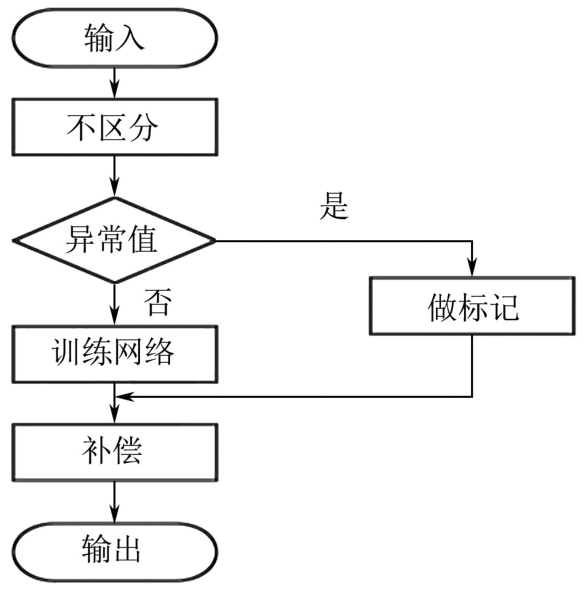

JIANG等[29]采用BP神经网络对异常值进行补偿,其流程图如图1所示。BP神经网络的两个信号同时循环,正向信号是预测信号,反向误差信号是校准信号。训练结果近似于输入值,则可保证数据预测的准确性。利用预测值对异常值进行补偿,然后在新数据中对异常值进行判别,结果显示第36个值不再被区分为异常值。因此,预测值是可信的。

1.3 数据缺口恢复

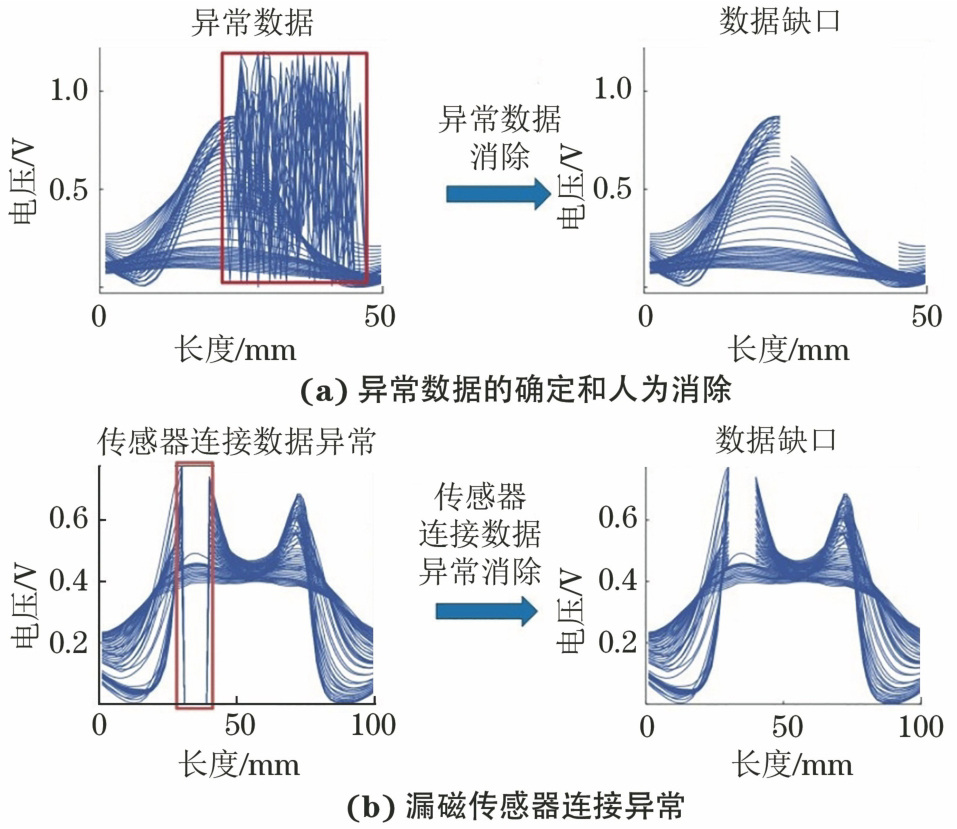

数据缺口恢复是漏磁数据处理中最重要的步骤之一[30]。在实际漏磁检测中,造成严重数据缺口的关键原因有以下几种:确定并人为消除异常数据,如图2(a)所示;漏磁传感器连接异常,如图2(b)所示;识别跨漏磁传感器波瓣的信号的一致性[31]。

漏磁数据中的任何位置都可能出现数据缺口。管道缺陷段的出现很可能形成数据缺口,这不仅影响缺陷位置的确定,而且严重影响缺陷尺寸的估计。数据缺口恢复主要有两种方法:基于完整字典的稀疏矩阵恢复算法[32]和基于数据驱动的学习算法[33-34]。

基于完整字典的稀疏矩阵恢复算法将列全秩矩阵构建为字典,其列是已知列向量的线性组合,并且系数是稀疏权重的线性组合[35]。压缩传感(CS)算法是数据恢复的经典字典学习方法之一[36],可用于无线传感器数据重建[37]、鲁棒数据恢复[38]和质谱数据处理[39]。压缩传感算法具有很强的弹性,但不适合工业领域的数据恢复。由于工业环境的复杂性,行业中的数据缺口是不确定的,因此很难保证数据矩阵的稀疏性[40]。完整字典的建立和优化是两个严重影响数据恢复准确性的问题[41]。此外,高精度的恢复结果需要经过多次迭代,花费时间较长,而行业中对数据处理的速度要求很高。

基于数据驱动的学习算法包括浅层神经网络和深层神经网络[42-43]。浅层神经网络主要包括支持向量回归(SVR)[44]和随机森林[45]。深度神经网络包括生成对抗性网络[46]、双向递归神经网络[47]、卷积递归神经网络[48]和堆叠式自动编码器[49]。学习算法是通过训练现有数据来预测未知数据。FENG等[50]将特征和相应的回归向量输入网络中,并训练网络参数,提出了一种快速径向基函数神经网络来重建漏磁检测中的缺陷轮廓。在分类和预测问题上,学习算法显示出强大的功能,但在恢复数据缺口方面受到限制。这是因为在实践中,很难为学习算法提供足够、整洁和充足的训练样本。此外,数据代表性特征提取困难也限制了学习算法的应用。因此,在较大的漏磁数据缺口中很难获得高精度恢复结果。

1.4 滤波

漏磁数据通常受到各种噪声源的污染,包括传感器提离变化引起的噪声,振动引起的噪声,无缝管道噪声(SPN)和系统噪声[51]。在这些噪声源中,无缝管道噪声在某些情况下可以完全掩盖来自某些类型缺陷的漏磁信号,例如来自浅层腐蚀和机械损伤的低信噪比(SNR)信号,这大大降低了管道缺陷的检出性。AFZAL等[52]提出了一种应用时域自适应滤波来消除无缝管道噪声的算法。然而,该算法的收敛速率取决于特征值扩散或自适应滤波器输入相关矩阵的最大与最小特征值之比,当该比值较大时,收敛速率较慢[53]。HOSUR等[54]提出一种利用小波变换域自适应有限脉冲响应(FIR)滤波算法的改进版本去除漏磁数据中SPN的方法,该算法不能直接应用于漏磁数据中SPN的去除,改进算法的收敛速率快于时域自适应SPN滤波算法。改进后算法不需要对原始漏磁数据进行数据归一化预处理以补偿数据收集机制中的缺陷,现场漏磁数据测试结果验证了改进算法的有效性。

2. 缺陷识别和量化方法

2.1 特征提取

管道漏磁检测中的关键问题是缺陷尺寸的识别和量化,缺陷尺寸量化的难点是漏磁缺陷信号特征参数的选择。刘金海等[55]从漏磁内检测数据中提取了能源特征、极值特征、信号强度特征、峰值特征、相似性特征和面积特征等6个参数作为特征参数,建立了缺陷的识别方法。刘玉明等[56]根据已有文献中常用的特征参数及信号统计方法,定义了以下5种特征参数获取方法:信号波形的峰谷值(轴向和径向信号的峰谷值)、信号的阈值截取长度(轴向和周向信号的阈值截取长度)、信号波形的面积(轴向和周向信号的波形面积)、信号波形的能量(轴向和周向信号的波形能量)、一次微分信号的峰谷值。然后,他们分析了特征参数与缺陷长度、宽度以及深度之间的相互影响关系。王少平等[57]分析了缺陷轴向检测信号的峰谷差、缺陷轴向检测信号的谷间距、缺陷轴向检测信号的波形面积、轴向波形面积与峰谷差之比、轴向波形面积与谷间距之比、漏磁场信号的轴向波形宽度、漏磁场信号的周向波形宽度、漏磁场信号的周向波形面积、周向波形面积与周向波形宽度之比等参数对漏磁信号的影响规律。

在大多数研究中,特征参数都是从漏磁信号中手动选择后进行训练,这些特征参数可能缺少对缺陷重建有用的信息。为了解决这个问题,ROSTAMI KANDROODI等[58]从漏磁信号剖面中提取缺陷长度和宽度,采用高斯径向基函数神经网络方法,以长度、宽度和径向信号波峰和谷值作为输入,预测缺陷深度。PIAO等[59]通过训练神经网络来估计缺陷的形状和大小。输入特征包括更多的物理参数,如最大幅度、峰间距离、平均值、标准差和归一化信号的积分,但目前关于这些物理参数对应缺陷特征映射效应的分析较少。ELLINGER等[60]提出了一种视觉转换的卷积神经网络,将原始漏磁信号直接输入其中可保留所有有用的信息。上述研究都证明了机器学习方法在缺陷检测中的重要性,使用神经网络旨在提高缺陷分类和量化的效率和准确性,节约手动选择的时间成本并减少计算错误。因此,根据外部因素的输入输出映射关系选择更好的特征值,并从内部优化神经网络是当前依靠神经网络进行缺陷检测的重中之重。

ZHANG等[61]从仿真得到的管道缺陷漏磁信号中提取主要特征参数用于缺陷识别。其中,径向检测信号的峰值与较大谷值之间差值的绝对值Bpp用于检测识别缺陷的宽度和深度;径向检测信号的谷值之间的差值DVV反映了缺陷泄漏磁场沿管道径向的信号分布,结合Bpp可以粗略地确定缺陷的形状,并定量识别缺陷的宽度和深度;轴向信号一阶导数峰值与较大谷值之间差值的绝对值Bdpp和两个谷值之差DDVV反映了缺陷磁场沿管道轴向的信号分布;径向检测信号的波形区域Sa由缺陷漏磁信号中的峰值和两个谷值组成。

2.2 缺陷识别和量化方法

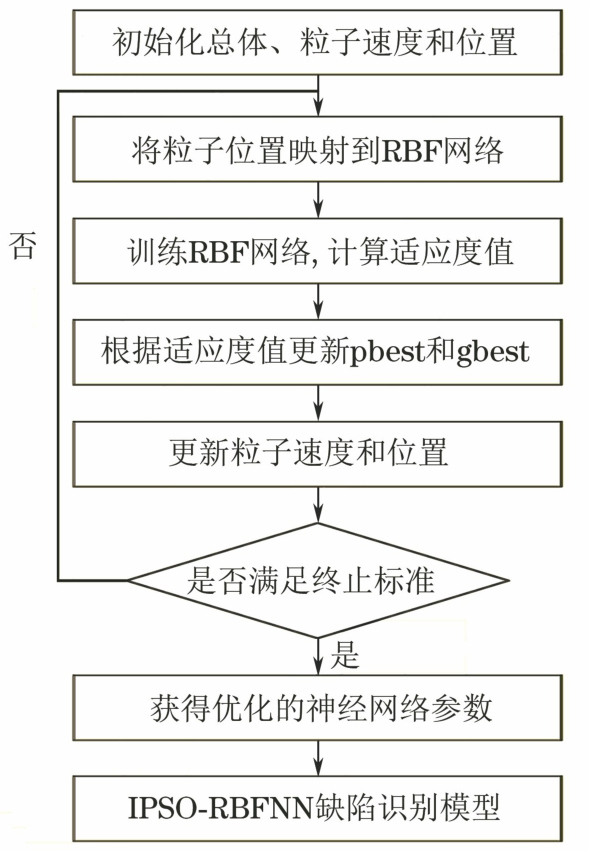

漏磁缺陷信号和管壁缺陷之间为非线性关系,这使得缺陷识别的难度陡增。为提高缺陷的识别率,专家和学者在现有算法基础上进行了多方面改进。ZHANG等[61]基于RBF神经网络(RBFNN)采用改进的粒子群算法(IPSO)选择最优参数,如图3所示。他们首先采用基于熵的策略初始化传统粒子群的种群,对惯性权重和学习因子进行改善;然后采用IPSO算法优化了RBFNN的中心、宽度和权重,从而缩短传统粒子群算法的搜索时间,降低落入局部最小值的可能性,提高RBFNN的识别精度。CHEN等[62]提出了一种BP神经网络的定量识别模型,用于激光超声检测过程中表面缺陷深度的定量识别。KANDROODI等[63]提出了一种基于图像处理和形态学方法的缺陷检测算法,并利用径向泄漏圆周分布估计管道上缺陷的宽度。该方法需要手动设置阈值和扩大缺陷标记范围,这使得后续工作更加困难。LIANG等[64]优化了花朵的授粉算法,采用改进的快速并行算法(IFPA)将无限折叠(ICMIC)与集成对立(CO)学习策略的迭代混沌图相结合,对BP神经网络进行优化。结果表明,该方法可以准确识别管道缺陷。

卷积神经网络(CNN)是一种深度前馈神经网络,基于CNN的算法在缺陷类型识别中的应用较多[65-69],在其他领域也有广泛应用[70-71]。KU M AR等[72]开发了一种新型CNN用于从小样本中识别轴承缺陷。基于CNN的识别算法已经比较成熟,CNN算法的可靠性在实际应用中也得到了证明[73-75]。然而,随着管道缺陷复杂性的增加,有必要进一步提高CNN的能力和准确性。WANG等[76]提出了一种基于CNN的缺陷尺寸预测方法,该方法可以有效识别管道的缺陷。LU等[77]提出了一种视觉变换卷积神经网络(VT-CNN)的方法,以解决特征提取的局限性,提高区分不同大小缺陷特征的精度。

目前,缺陷重建的研究工作主要包括基于支持向量机和神经网络构建反演模型[78-79]。WANG等[80]构建了缺陷反演的BP神经网络模型,用于漏磁定量检测。结果表明,BP神经网络能够根据漏磁信号预测缺陷的几何参数,为漏磁的定量检测提供了一种可行的方法。CHEN等[81]利用径向基函数神经网络预测缺陷轮廓,并结合梯度下降和模拟退火方法,提高了缺陷轮廓反演的精度。

针对如何使用CNN半监督学习方法识别钢表面缺陷的问题,GAO等[82]提出了通过伪标签改进CNN的方法,以提高缺陷识别的准确性。从试验数据可以推断,在小样本的情况下该方法显示出更好的结果。LE等[83]提出使用深度神经网络代替有限元模拟的方法。该方法简化了网格划分等复杂步骤。SUN等[84]提出了一种通过自适应多尺度图像采集(AMIC)增加训练数据集的方法,以改进基于CNN的表面缺陷检测模型。QIU等[85]提出利用主成分分析(PCA)改进GA-BP神经网络,实现预测微裂纹宽度和深度的功能。结果表明,该方法在定量鉴定方面是有效的。

在缺陷重构问题中,如何优化算法决定了整个缺陷反演方法的迭代次数和反演精度。FEI等[86]采用单维进化策略进行补充,优化了传统的粒子群算法。优化后算法提高了缺陷轮廓重建的精度。

邱忠超等[87]提出了利用遗传算法优化BP神经网络进行裂纹定量识别的方法,以提高识别精度。结果表明,该方法可以识别1 mm以下的裂纹。WANG等[88]利用遗传算法改进BP神经网络对铁磁钢裂纹的定量检测,并对裂纹进行反向特征分析。ZHANG等[89]提出了一种基于粒子群算法的矩形裂纹尺寸重建方法,以解决不同提离值和不同磁场下裂纹尺寸的重建问题。

HAN等[90]使用高维高效管理粒子群优化(EMPSO)估计缺陷轮廓,并将基于EMPSO的反演方法与基于自学习粒子优化算法(SLPSO)的反演方法进行了比较。结果表明,基于EMPSO的反演方法具有较高的精度。

HAMED等[91]提出了一种新的混合标定模型,该模型基于两步K最近邻插值和支持向量回归。在校准过程中,该混合模型同时使用一般和局部估算以提高其预测准确性。该方法将漏磁测量误差从原来的±20%降低到±6.82%。

3. 结束语

漏磁内检测数据处理是一个复杂的过程,不同的预处理和缺陷识别量化方法呈现出不同的量化精度。虽然关于漏磁数据预处理和缺陷识别量化方法的研究取得了一定的成果,但是对应缺陷数据量化的可信度还存在商榷。通过机器学习算法的不断衍生,形成了一系列可靠的多种算法结合的缺陷识别量化方法。油气田的勘探开发逐渐向井下和条件更为恶劣的地区发展,为满足开采要求,双金属复合管或者其他管材被逐渐采用,因此漏磁内检测在弱磁、厚壁管、强腐蚀性介质、三元复杂体系下的数据预处理和缺陷识别量化技术是未来的研究方向。

-

-

[1] FU M R, LIU J H, ZANG D, et al. Anomaly detection of complex MFL measurements using low-rank recovery in pipeline transportation inspection [J]. IEEE Transactions on Instrumentation and Measurement, 2020, 69(9): 6776-6786. [2] HEO C G, IM S H, JEONG H S, et al. Magnetic hysteresis analysis of a pipeline re-inspection by using preisach model [J]. IEEE Transactions on Magnetics, 2020, 56(3): 6702004. [3] JOSHI A V, UDPA L, UDPA S, et alAdaptive wavelets for characterizing magnetic flux leakage signals from pipeline inspection2006 IEEE International Magnetics Conference (INTERMAG)San DiegoIEEE2006652JOSHI A V, UDPA L, UDPA S, et al. Adaptive wavelets for characterizing magnetic flux leakage signals from pipeline inspection [C]//2006 IEEE International Magnetics Conference (INTERMAG). San Diego:IEEE, 2006: 652. [4] AMINEH R K, KOZIEL S, NIKOLOVA N K, et al. A space mapping methodology for defect characterization from magnetic flux leakage measurements [J]. IEEE Transactions on Magnetics, 2008, 44(8): 2058-2065. [5] WANG L, ZHANG H G, LIU J H, et al. Defect size quantification for pipeline magnetic flux leakage detection system via multilevel knowledge-guided neural network [J]. IEEE Transactions on Industrial Electronics, 2023, 70(9): 9550-9560. [6] SHI Y, ZHANG C, LI R, et al. Theory and application of magnetic flux leakage pipeline detection [J]. Sensors, 2015, 15(12): 31036-31055. [7] XIE M J, TIAN Z G. A review on pipeline integrity management utilizing in-line inspection data [J]. Engineering Failure Analysis, 2018, 92: 222-239. [8] SONG H D, YANG L, LIU G H, et al. Comparative analysis of In-line inspection equipments and technologies [J]. IOP Conference Series: Materials Science and Engineering, 2018, 382: 032021. [9] 王秀丽, 朱晓红, 夏飞, 等.管道内检测技术及标准体系发展现状 [J]. 石油化工自动化, 2018, 54(2): 1-5. [10] PAN J H, GAO L. A novel method for defects marking and classifying in MFL inspection of pipeline [J]. International Journal of Pressure Vessels and Piping, 2023, 202: 104892. [11] JUNG J W, LIM M S, HONG J P, et al. Characteristics analysis of SPMSM using 2-D finite-element analysis considering axial leakage flux [J]. IEEE Transactions on Magnetics, 2018, 54(3): 8200904. [12] LIN T Y, DOLLÁR P, GIRSHICK R, et alFeature pyramid networks for object detection2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR)IEEE2017936944LIN T Y, DOLLÁR P, GIRSHICK R, et al. Feature pyramid networks for object detection [C]//2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR). [S.l.]:IEEE, 2017: 936-944. [13] HE K M, ZHANG X Y, REN S Q, et alDeep residual learning for image recognition2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR)IEEE2016770778HE K M, ZHANG X Y, REN S Q, et al. Deep residual learning for image recognition [C]//2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR). [S.l.]:IEEE, 2016: 770-778. [14] SHI P P, BAI P G, CHEN H E, et al. The magneto-elastoplastic coupling effect on the magnetic flux leakage signal [J]. Journal of Magnetism and Magnetic Materials, 2020, 504: 166669. [15] JIA Y L, LIANG K W, WANG P, et al. Enhancement method of magnetic flux leakage signals for rail track surface defect detection [J]. IET Science, Measurement & Technology, 2020, 14(6): 711-717. [16] LIU Z, KLEINER Y. State of the art review of inspection technologies for condition assessment of water pipes [J]. Measurement, 2013, 46(1): 1-15. [17] 王坤, 韩文花, 王海航.基于改进信赖域算法的三维不规则缺陷重构 [J]. 仪器仪表学报, 2021, 42(10): 129-137. [18] YU Z Y, LI Y, JING Y T, et al. An improved subdomain model for magnetic field calculation of SPMSM considering no-load leakage flux [J]. Journal of Electrical Engineering & Technology, 2020, 15(6): 2651-2660. [19] MIU L H, PAN F, LPENG S, et al. Iterative optimization method of defect depth profile based on depth characteristics of MFL signalProceedings of the CSEE202242830773086MIU L H, PAN F, L. PENG S, et al. Iterative optimization method of defect depth profile based on depth characteristics of MFL signal [C]//Proceedings of the CSEE. [S.l.]: [s.n.], 2022, 42(8): 3077-3086. [20] 陈彦彤, 徐伟, 朴永杰, 等.基于快速视网膜局部特征的遥感图像目标识别 [J]. 仪器仪表学报, 2016, 37(4): 852-859. [21] 周显恩, 王耀南, 朱青, 等.基于机器视觉的瓶口缺陷检测方法研究 [J]. 电子测量与仪器学报, 2016, 30(5): 702-713. [22] DRURY J C, MARINO AA comparison of the magnetic flux leakage and ultrasonic methods in the detection and measurement of corrosion pitting in ferrous plate and pipeProceeding of 15th World Conference on Nondestructive Testing2000DRURY J C, MARINO A. A comparison of the magnetic flux leakage and ultrasonic methods in the detection and measurement of corrosion pitting in ferrous plate and pipe [C]//Proceeding of 15th World Conference on Nondestructive Testing. [S.l.]: [s.n.], 2000. [23] 刘金海, 赵贺, 神祥凯, 等.基于漏磁内检测的自监督缺陷检测方法 [J]. 仪器仪表学报, 2020, 41(9): 180-187. [24] MUKHERJEE D, SAHA S, MUKHOPADHYAY S. An adaptive channel equalization algorithm for MFL signal [J]. NDT & E International, 2012, 45(1): 111-119. [25] FRIEDLAND B. Control systems design: an introduction to state-space methods [M]. [S.l.]: McGraw-Hill Higher Education. 1996. [26] 许必宵, 陈升波, 韩重阳, 等.改进的数据预处理算法及其应用 [J]. 计算机技术与发展, 2015, 25(12): 143-146,151. [27] 杨理践, 耿浩, 高松巍.长输油气管道漏磁内检测技术 [J]. 仪器仪表学报, 2016, 37(8): 1736-1746. [28] 高松巍, 郑树林, 杨理践.长输管道漏磁内检测缺陷识别方法 [J]. 无损检测, 2013, 35(1): 38-41. [29] JIANG L, LIU J H, ZHANG H G, et alDiscrimination and compensation of abnormal values of magnetic flux leakage in oil pipeline based on BP neural network2017 29th Chinese Control and Decision Conference (CCDC)IEEE201737143718JIANG L, LIU J H, ZHANG H G, et al. Discrimination and compensation of abnormal values of magnetic flux leakage in oil pipeline based on BP neural network [C]//2017 29th Chinese Control and Decision Conference (CCDC). [S.l.]:IEEE, 2017: 3714-3718. [30] LI D, ZHOU Y X, HU G Q, et al. Identifying unseen faults for smart buildings by incorporating expert knowledge with data [J]. IEEE Transactions on Automation Science and Engineering, 2019, 16(3): 1412-1425. [31] ZHANG H G, JIANG L, LIU J H, et al. Data recovery of magnetic flux leakage data gaps using multifeature conditional risk [J]. IEEE Transactions on Automation Science and Engineering, 2021, 18(3): 1064-1073. [32] RAMBHATLA S, LI X G, HAUPT JNOODL: provable online dictionary learning and sparse codingInternational Conference on Learning Representations (ICLR) 20192023-09-23 https://arxiv.org/pdf/1902.11261.pdfRAMBHATLA" target="_blank"> https://arxiv.org/pdf/1902.11261.pdfRAMBHATLA S, LI X G, HAUPT J.NOODL: provable online dictionary learning and sparse coding [C/OL]//International Conference on Learning Representations (ICLR) 2019. [2023-09-23]. https://arxiv.org/pdf/1902.11261.pdf. [33] WU J J, DENG L, JEON G. Image autoregressive interpolation model using GPU-parallel optimization [J]. IEEE Transactions on Industrial Informatics, 2018, 14(2): 426-436. [34] HU L, LEE K M, ZOU J, et al. Adaptive measurement for automated field reconstruction and calibration of magnetic systems [J]. IEEE Transactions on Automation Science and Engineering, 2011, 8(2): 327-337. [35] ZHANG K, ZHANG H G, MU Y F, et al. Decentralized tracking optimization control for partially unknown fuzzy interconnected systems via reinforcement learning method [J]. IEEE Transactions on Fuzzy Systems, 2021, 29(4): 917-926. [36] PEREPU S K, TANGIRALA A K. Reconstruction of missing data using compressed sensing techniques with adaptive dictionary [J]. Journal of Process Control, 2016, 47: 175-190. [37] CAO G M, JUNG P, STAŃCZAK S, et al. Data aggregation and recovery in wireless sensor networks using compressed sensing [J]. International Journal of Sensor Networks, 2016, 22(4): 209-219. [38] YANG Y C, NAGARAJAIAH S. Robust data transmission and recovery of images by compressed sensing for structural health diagnosis [J]. Structural Control and Health Monitoring, 2017, 24(1): e1856. [39] LIU J X, SUN Q SMass spectrum data processing based on compressed sensing recognition and sparse difference recovery2012 9th International Conference on Fuzzy Systems and Knowledge DiscoveryIEEE201214131417LIU J X, SUN Q S. Mass spectrum data processing based on compressed sensing recognition and sparse difference recovery [C]//2012 9th International Conference on Fuzzy Systems and Knowledge Discovery. [S.l.]:IEEE, 2012: 1413-1417. [40] PUTHENPUTHUSSERY A, LIU Q F, LIU C J. A sparse representation model using the complete marginal fisher analysis framework and its applications to visual recognition [J]. IEEE Transactions on Multimedia, 2017, 19(8): 1757-1770. [41] KHAN I, XU Y L, KAR S, et al. Compressive sensing and morphology singular entropy-based real-time secondary voltage control of multiarea power systems [J]. IEEE Transactions on Industrial Informatics, 2019, 15(7): 3796-3807. [42] XIE Q, LI D W, XU J X, et al. Automatic detection and classification of sewer defects via hierarchical deep learning [J]. IEEE Transactions on Automation Science and Engineering, 2019, 16(4): 1836-1847. [43] LI Y D, ZHAO W G, PAN J H. Deformable patterned fabric defect detection with fisher criterion-based deep learning [J]. IEEE Transactions on Automation Science and Engineering, 2017, 14(2): 1256-1264. [44] LIU Z Y, XU Y K, QIU C, et al. A novel support vector regression algorithm incorporated with prior knowledge and error compensation for small datasets [J]. Neural Computing and Applications, 2019, 31(9): 4849-4864. [45] HUANG J J, SIU W C, LIU T R. Fast image interpolation via random forests [J]. IEEE Transactions on Image Processing: a Publication of the IEEE Signal Processing Society, 2015, 24(10): 3232-3245. [46] QU F M, LIU J H, MA Y J, et al. A novel wind turbine data imputation method with multiple optimizations based on GANs [J]. Mechanical Systems and Signal Processing, 2020, 139: 106610. [47] JEONG S, FERGUSON M, HOU R, et al. Sensor data reconstruction using bidirectional recurrent neural network with application to bridge monitoring [J]. Advanced Engineering Informatics, 2019, 42: 100991. [48] QIN C, SCHLEMPER J, CABALLERO J, et al. Convolutional recurrent neural networks for dynamic MR image reconstruction [J]. IEEE Transactions on Medical Imaging, 2019, 38(1): 280-290. [49] KHODAYAR M, KAYNAK O, KHODAYAR M E. Rough deep neural architecture for short-term wind speed forecasting [J]. IEEE Transactions on Industrial Informatics, 2017, 13(6): 2770-2779. [50] FENG J, LI F M, LU S X, et al. Fast reconstruction of defect profiles from magnetic flux leakage measurements using a RBFNN based error adjustment methodology [J]. IET Science, Measurement & Technology, 2017, 11(3): 262-269. [51] LIM JData fusion for NDE signal characterizationAmesIowa State University2001LIM J. Data fusion for NDE signal characterization [D]. Ames: Iowa State University, 2001. [52] AFZAL M, UDPA S. Advanced signal processing of magnetic flux leakage data obtained from seamless gas pipeline [J]. NDT & E International, 2002, 35(7): 449-457. [53] WIDROW B, MCCOOL J M, LARIMORE M G, et al. Stationary and nonstationary learning characteristics of the LMS adaptive filter [J]. Proceedings of the IEEE, 1976, 64(8): 1151-1162. [54] HOSUR S, TEWFIK A H. Wavelet transform domain adaptive FIR filtering [J]. IEEE Transactions on Signal Processing, 1997, 45(3): 617-630. [55] 刘金海, 付明芮, 唐建华.基于漏磁内检测的缺陷识别方法 [J]. 仪器仪表学报, 2016, 37(11): 2572-2581. [56] 刘玉明, 王继锋, 汤晓英, 等.管道漏磁检测缺陷尺寸与信号特征参数关系分析 [J]. 石油化工设备, 2021, 50(6): 9-14. [57] 王少平, 王增国, 刘金海, 等.基于三轴漏磁与电涡流检测的管道内外壁缺陷识别方法 [J]. 控制工程, 2014, 21(4): 572-578. [58] ROSTAMI KANDROODI M, NADJAR ARAABI B, MANSOOB BASSIRI M, et al. Estimation of depth and length of defects from magnetic flux leakage measurements: verification with simulations, experiments, and pigging data [J]. IEEE Transactions on Magnetics, 2017, 53(3): 6200310. [59] PIAO G Y, GUO J B, HU T H, et al. Fast reconstruction of 3-D defect profile from MFL signals using key physics-based parameters and SVM [J]. NDT & E International, 2019, 103: 26-38. [60] ELLINGER M A, BUBENIK T A, MORENO P JILI-to-field data comparisons: what accuracy can you expect?Proceedings of 2016 11th International Pipeline ConferenceCalgary, Alberta, Canada2016ELLINGER M A, BUBENIK T A, MORENO P J. ILI-to-field data comparisons: what accuracy can you expect? [C]//Proceedings of 2016 11th International Pipeline Conference. Calgary, Alberta, Canada: [s.n.], 2016. [61] ZHANG H, YU X J. Research on oil and gas pipeline defect recognition based on IPSO for RBF neural network [J]. Sustainable Computing: Informatics and Systems, 2018, 20: 203-209. [62] 陈超, 张兴媛, 陆思烨.基于优化BP神经网络激光超声表面缺陷识别 [J]. 激光与光电子学进展,2021,58(22):505-515. [63] KANDROODI M R, ARAABI B N, AHMADABADI M N, et alDetection of natural gas pipeline defects using magnetic flux leakage measurements2013 21st Iranian Conference on Electrical Engineering (ICEE)IEEE201316KANDROODI M R, ARAABI B N, AHMADABADI M N, et al. Detection of natural gas pipeline defects using magnetic flux leakage measurements [C]//2013 21st Iranian Conference on Electrical Engineering (ICEE). [S.l.]:IEEE, 2013: 1-6. [64] LIANG X B, LIANG W, XIONG J Y. Intelligent diagnosis of natural gas pipeline defects using improved flower pollination algorithm and artificial neural network [J]. Journal of Cleaner Production, 2020, 264: 121655. [65] XIE Y C, XIAO Y C, LIU X Y, et al. Time-frequency distribution map-based convolutional neural network (CNN) model for underwater pipeline leakage detection using acoustic signals [J]. Sensors, 2020, 20(18): 5040. [66] FENG J, LI F M, LU S X, et al. Injurious or noninjurious defect identification from MFL images in pipeline inspection using convolutional neural network [J]. IEEE Transactions on Instrumentation and Measurement, 2017, 66(7): 1883-1892. [67] HOANG N D, TRAN V D. Image processing-based detection of pipe corrosion using texture analysis and metaheuristic-optimized machine learning approach [J]. Computational Intelligence and Neuroscience, 2019, 2019: 8097213. [68] ALOYSIUS N, GEETHA MA review on deep convolutional neural networks2017 International Conference on Communication and Signal Processing (ICCSP)IEEE2017588592ALOYSIUS N, GEETHA M. A review on deep convolutional neural networks [C]//2017 International Conference on Communication and Signal Processing (ICCSP). [S.l.]:IEEE, 2017: 588-592. [69] SHARMA N, JAIN V, MISHRA A. An analysis of convolutional neural networks for image classification [J]. Procedia Computer Science, 2018, 132: 377-384. [70] FRIKHA M S, GAMMAR S M, LAHMADI A, et al. Reinforcement and deep reinforcement learning for wireless Internet of Things: a survey [J]. Computer Communications, 2021, 178: 98-113. [71] JIANG S, CAO J N, WU H Q, et al. Fairness-based packing of industrial IoT data in permissioned blockchains [J]. IEEE Transactions on Industrial Informatics, 2021, 17(11): 7639-7649. [72] KUMAR A, VASHISHTHA G, GANDHI C P, et al. Novel convolutional neural network (NCNN) for the diagnosis of bearing defects in rotary machinery [J]. IEEE Transactions on Instrumentation and Measurement, 1809, 70: 3510710. [73] IQBAL S, GHANI M U, SABA T, et al. Brain tumor segmentation in multi-spectral MRI using convolutional neural networks (CNN) [J]. Microscopy Research and Technique, 2018, 81(4): 419-427. [74] CHUNG E, FOWERS J, OVTCHAROV K, et al. Serving DNNs in real time at datacenter scale with project brainwave [J]. IEEE Micro, 2018, 38(2): 8-20. [75] HUANG L Q, LI J, HAO H, et al. Micro-seismic event detection and location in underground mines by using convolutional neural networks (CNN) and deep learning [J]. Tunnelling and Underground Space Technology, 2018, 81: 265-276. [76] WANG H A, CHEN G M. Defect size estimation method for magnetic flux leakage signals using convolutional neural networks [J]. Insight - Non-Destructive Testing and Condition Monitoring, 2020, 62(2): 86-91. [77] LU S X, FENG J, ZHANG H G, et al. An estimation method of defect size from MFL image using visual transformation convolutional neural network [J]. IEEE Transactions on Industrial Informatics, 2019, 15(1): 213-224. [78] GOLODOV V A, MALTSEVA A A. Approach to weld segmentation and defect classification in radiographic images of pipe welds [J]. NDT & E International, 2022, 127: 102597. [79] CHEN B Z, FANG Z H, XIA Y, et al. Accurate defect detection via sparsity reconstruction for weld radiographs [J]. NDT & E International, 2018, 94: 62-69. [80] WANG C L, LIU B, JI F Z, et al. Quantitative testing of magnetic flux leakage based on BP neural networks [J]. Materials Science and Engineering,2007. [81] CHEN J J, HUANG S L, ZHAO W. Three-dimensional defect inversion from magnetic flux leakage signals using iterative neural network [J]. IET Science, Measurement & Technology, 2015, 9(4): 418-426. [82] GAO Y P, GAO L, LI X Y, et al. A semi-supervised convolutional neural network-based method for steel surface defect recognition [J]. Robotics and Computer-Integrated Manufacturing, 2020, 61: 101825. [83] LE M, PHAM C T, LEE J Y. Deep neural network for simulation of magnetic flux leakage testing [J]. Measurement, 2021, 170: 108726. [84] SUN J, WANG P, LUO Y K, et al. Surface defects detection based on adaptive multiscale image collection and convolutional neural networks [J]. IEEE Transactions on Instrumentation and Measurement, 2019, 68(12): 4787-4797. [85] QIU Z C, ZHANG R L, ZHANG W M, et al. Quantitative identification of microcracks through magnetic flux leakage testing based on improved back-propagation neural network [J]. Insight - Non-Destructive Testing and Condition Monitoring, 2019, 61(2): 90-94. [86] FEI S G, LIU G H, FEI J Y, et al. Defect reconstruction of magnetic flux leakage measurements based on single dimension PSO algorithm [J]. Journal of Physics: Conference Series, 2021, 1948(1): 012008. [87] 邱忠超, 张卫民, 张瑞蕾, 等.基于GA-BP神经网络的微裂纹漏磁定量识别技术 [J]. 北京理工大学学报, 2016, 36(11): 1101-1104,1121. [88] WANG Z W, FEI Y, YE P X, et al. Crack characterization in ferromagnetic steels by pulsed eddy current technique based on GA-BP neural network model [J]. Journal of Magnetism and Magnetic Materials, 2020, 500: 166412. [89] ZHANG Y, YE Z F, WANG C. A fast method for rectangular crack sizes reconstruction in magnetic flux leakage testing [J]. NDT & E International, 2009, 42(5): 369-375. [90] HAN W H, XU J, WANG P, et al. Defect profile estimation from magnetic flux leakage signal via efficient managing particle swarm optimization [J]. Sensors, 2014, 14(6): 10361-10380. [91] HAMED Y, IBRAHIM ALZAHRANI A, SHAFIE A, et al. Two steps hybrid calibration algorithm of support vector regression and K-nearest neighbors [J]. Alexandria Engineering Journal, 2020, 59(3): 1181-1190. -

期刊类型引用(2)

1. 王轲,黄成橙,王鹏. 深度学习在油气管道漏磁检测领域的应用. 无损检测. 2024(12): 93-99 .  百度学术

百度学术

2. 赵赏鑫,田野. 基于PP-YOLOE与MTL的管道腐蚀缺陷识别量化方法. 油气储运. 2024(12): 1355-1364 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: