Effect of Chemical Milling Parameters on AFM of TA15 Titanium Alloy

-

摘要:

分别研究了搅拌速率、溶液配比、摆放位置、化铣时间、添加剂含量和化铣温度等化学铣切(化铣)参数对TA15钛合金显微形貌的影响,并采用原子力显微镜(AFM)表征其形貌。结果表明:增加搅拌速率、溶液配比、化铣时间和添加剂都会使得化铣之后表面粗糙度减少;随化铣温度增加,表面粗糙度先增加后减小;摆放位置对TA15钛合金表面粗糙度的影响较小。

-

关键词:

- 化铣 /

- 参数 /

- TA15钛合金 /

- 显微形貌 /

- 原子力显微镜(AFM)

Abstract:The effects of chemical milling parameters such as stirring speed, solution ratio, placement position, chemical milling time, additive content, and chemical milling temperature on the microstructure of TA15 titanium alloy were investigated in this experiment, and the morphology of the allay was characterized by atomic force microscope (AFM). The results show that increasing the stirring speed, solution ratio, chemical milling time, and additives would make surface roughness of TA15 titanium alloy decreases. As the chemical milling temperature increased, surface roughness increased first and then decreased. The placement position had little effect on the surface roughness of TA15 titanium alloy.

-

Keywords:

- chemical milling /

- parameter /

- TA15 titanium alloy /

- microstructure /

- AFM

-

钛合金作为典型的高强度合金材料,具有耐蚀性良好、密度小、减震性能好以及比强度高等优点,在航空航天等方面得到了广泛的应用。但是,钛合金加工难度较大,表面粗糙度难以控制,而表面粗糙度是表面完整性最重要的评价指标之一,其对构件的疲劳性能、应力腐蚀性能等具有重要作用[1-16]。表面粗糙度越大,表面的沟痕越深,纹底半径越小,应力集中越严重,抗疲劳破坏和抗应力腐蚀的能力就越差,因此表面粗糙度增大,会降低零件的疲劳强度和抗应力腐蚀的能力。TA15钛合金(简称TA15)对应力比较敏感,合理控制化学铣切参数能够减少零件的应力集中,降低TA15工件表面粗糙度,使得加工质量达到最佳。

本工作研究了化铣工艺参数:如搅拌速率、溶液配比、摆放位置、化铣时间、添加剂含量和化铣温度等对TA15表面粗糙度的影响,并采用原子力显微镜(AFM)对其进行表征。

1. 试验

试验所用TA15板材由宝鸡市嘉祥金属材料有限公司提供,按照GB/T3621-2007《钛及钛合金板材标准》,采用冷轧退火处理,化学成分见表1。

表 1 TA15的化学成分Table 1. Chemical composition of TA15元素 Ti Al V Mo Zr Si Fe C N H 其他 质量分数/% 87.87 6.46 1.7 1.38 2.16 0.024 0.096 0.016 0.016 0.002 <0.10 化铣溶液体系包括:氢氟酸、硝酸、十二烷基硫酸钠、乙二醇单丁醚和尿素。

改变化铣工艺参数:如搅拌速率、溶液配比、化铣时间、添加剂含量、化铣温度及摆放位置等对TA15钛合金进行化铣,并采用AFM5500M型日立全自动型原子力显微镜表征化铣后试样的显微形貌。

2. 结果与讨论

2.1 TA15钛合金的AFM形貌

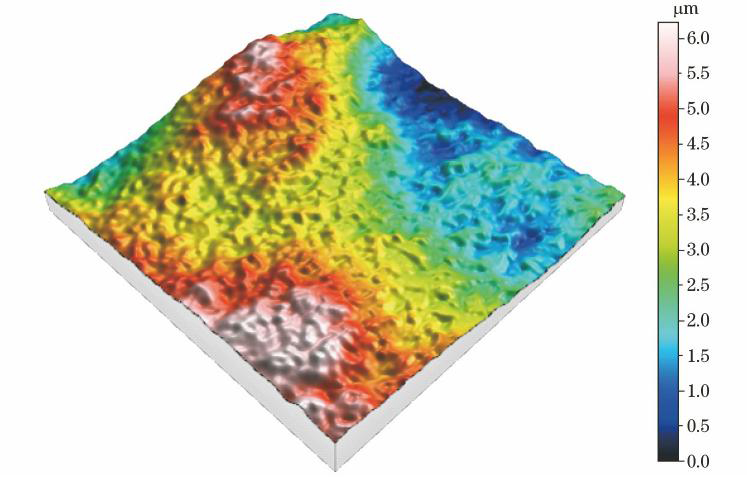

对TA15板材的组织结构进行AFM表征,如图1所示,TA15表面粗糙度为1.15 μm。

2.2 化铣工艺对TA15钛合金AFM形貌的影响

2.2.1 搅拌速率的影响

腐蚀溶液组成:氢氟酸75 mL/L、硝酸150 mL/L、十二烷基硫酸钠0.2 g/L、乙二醇单丁醚30 mL/L,尿素10 g/L,温度为30 ℃。由图2可知,与未搅拌试样相比,当腐蚀溶液搅拌速率为300 r/min时,试样表面粗糙度相对较大,两者的表面粗糙度分别为0.520 μm和0.581 μm,而当搅拌速率为500 r/min和600 r/min时,其表面粗糙度分别为0.327 μm和0.192 μm。这说明随着搅拌速率的增加,表面粗糙度有变小的趋势且表面会变的更加均匀。

2.2.2 溶液配比的影响

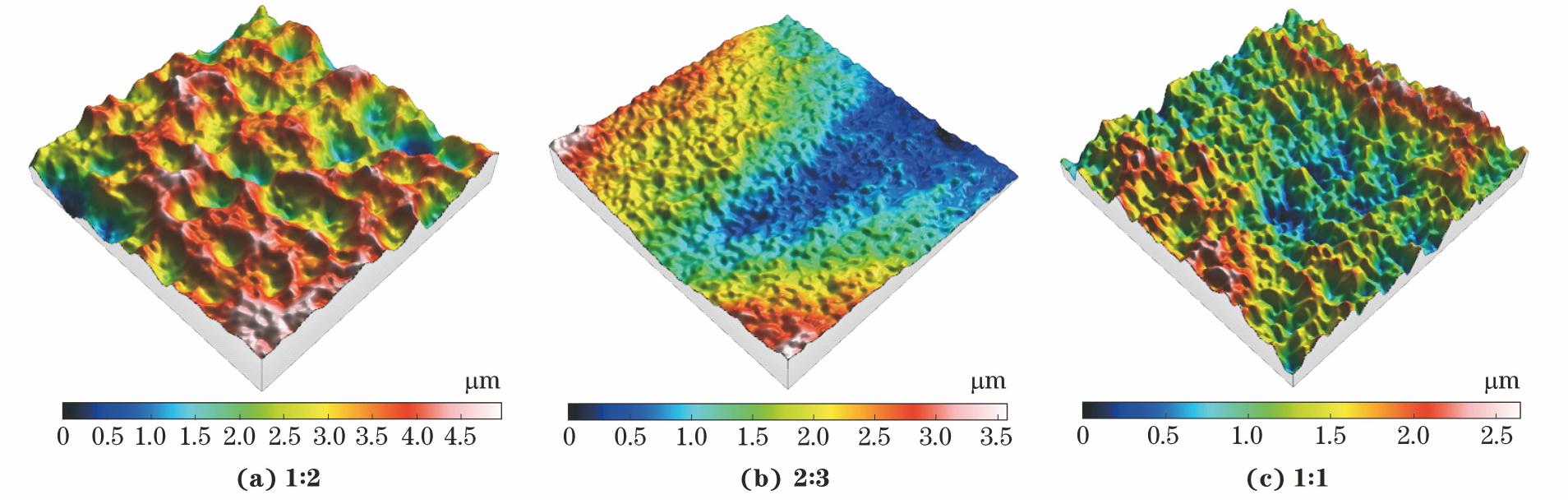

腐蚀溶液组成:十二烷基硫酸钠0.2 g/L、乙二醇单丁醚30 mL/L,尿素10 g/L,温度为30 ℃。

由图3可知,在本试验条件下,随着HF量的增加,表面粗糙度分别为0.627、0.616和0.353 μm,TA15钛合金的表面变得更加均匀,说明随着HF量的增加,其表面粗糙度有降低的趋势。

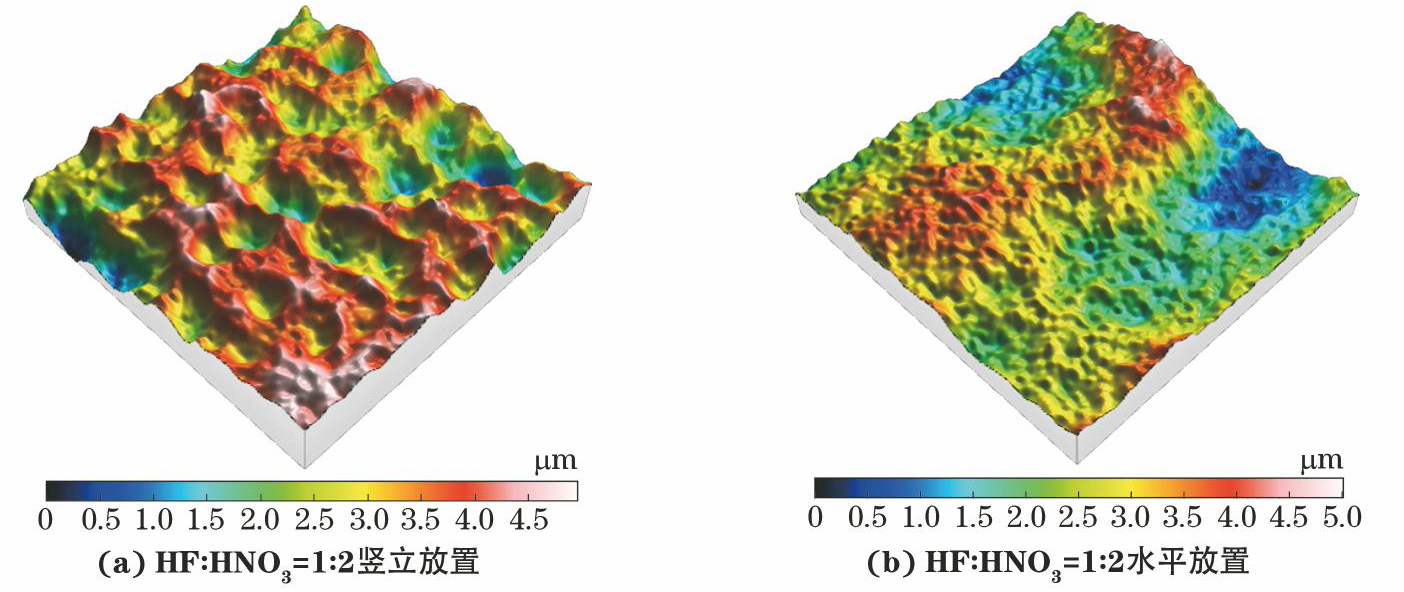

2.2.3 摆放位置的影响

腐蚀溶液组成:氢氟酸75 mL/L、硝酸150 mL/L、十二烷基硫酸钠0.2 g/L、乙二醇单丁醚30 mL/L,尿素10 g/L,温度为50 ℃。采用竖直放置与水平放置两种方式研究TA15化铣后,其表面AFM形貌状况,如图4所示。由图4可知,两者的表面粗糙度相近,分别为0.627 μm和0.691 μm,说明放置位置对试样表面粗糙度影响较小。

2.2.4 化铣时间的影响

腐蚀溶液组成:氢氟酸75 mL/L、硝酸150 mL/L、十二烷基硫酸钠0.2 g/L、乙二醇单丁醚30 mL/L,尿素10 g/L,温度为30 ℃。

图5为不同化铣时间下,TA15钛合金的表面形貌,可以看出,表面粗糙度分别为1.280,0.772,0.747,0.305 μm,说明随着化铣时间的增加,试样表面逐渐变得均匀,且表面粗糙度逐渐降低。

2.2.5 添加剂含量的影响

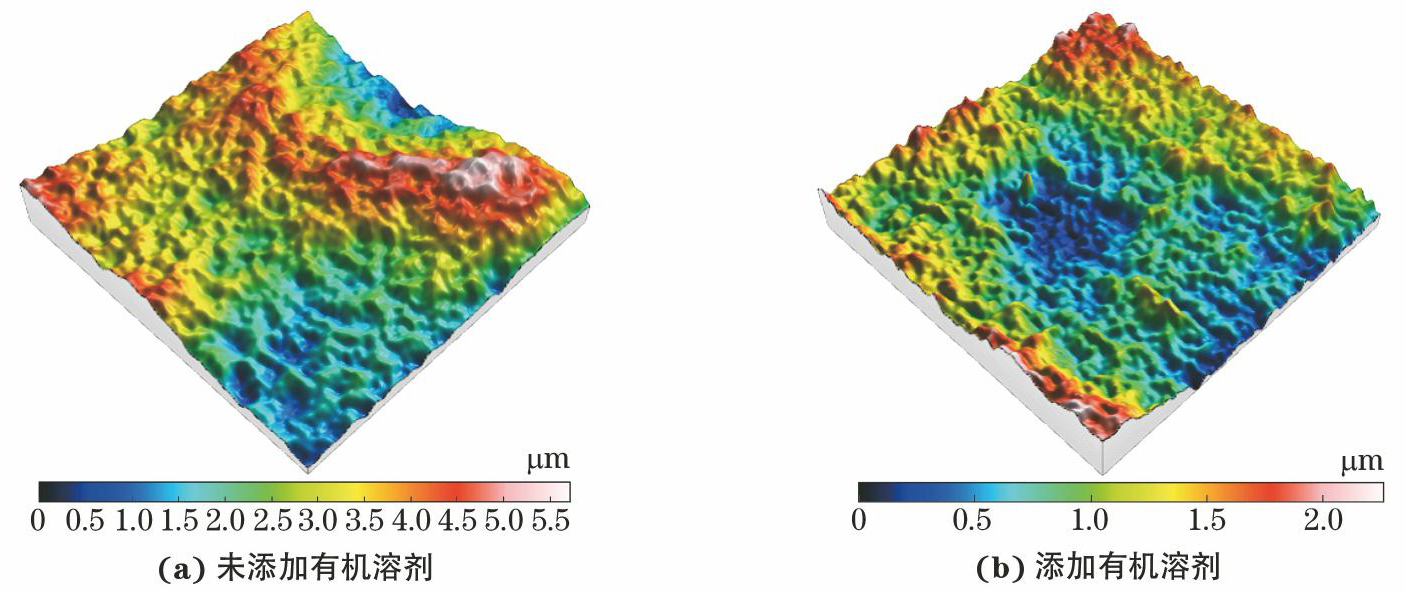

腐蚀溶液组成:氢氟酸75 mL/L、硝酸150 mL/L、十二烷基硫酸钠0.2 g/L、乙二醇单丁醚30 mL/L,尿素10 g/L,温度维持在30 ℃,化铣时间3 h。

采用未添加与添加十二烷基硫酸钠(SDS)、脲、丁二醇单丁醚的HF+HNO3溶液对TA15钛合金表面化铣后,由图6可知,未添加有机溶剂时,试样表面不均匀且粗糙度大,表面粗糙度为0.864 μm;而添加有机溶剂后,表面粗糙度为0.327 μm,试样表面变得相对均匀且粗糙度明显降低。

2.2.6 化铣温度的影响

腐蚀溶液组成:氢氟酸75 mL/L、硝酸150 mL/L、十二烷基硫酸钠0.2 g/L、乙二醇单丁醚30 mL/L,尿素10 g/L,化铣时间3 h。

由图7可见,当化铣温度为20,30,40,50,60 ℃时,试样表面粗糙度分别为0.307,0.351,1.34,0.834,0.421μm。即随着温度的升高,TA15钛合金表面的粗糙度呈现先增加后减小的趋势。这种变化趋势主要是由于温度升高促进腐蚀产物的扩散提高腐蚀速率,与温度升高促进HF挥发降低腐蚀速率间的相互制约。

3. 结论

(1)随着搅拌速率的增加,化铣后试样的表面粗糙度变小且表面变得更加均匀,当搅拌速率为500 r/min和600 r/min时,表面粗糙度分别为0.327 μm和0.192 μm。

(2)当化铣溶液中HF与HNO3的体积比分别为1∶2,2∶3,1∶1时,化铣后试样的表面粗糙度分别0.627,0.616,0.353 μm,即随着HF与HNO3体积比的升高,TA15钛合金表面粗糙度有降低的趋势。

(3)当化铣时间为0.5,1,2,3 h时,化铣后试样的表面粗糙度分别为1.28,0.772,0.747,0.305 μm,即随着化铣时间的增加,试样表面粗糙度逐渐降低。

(4)当化铣溶液中无添加剂时,化铣后试样的表面粗糙度为0.864 μm,而添加有机溶剂,化铣后试样的表面粗糙度为0.327 μm。

(5)当化铣温度为20,30,40,50,60 ℃时,化铣后试样的表面粗糙度分别为0.307,0.351,1.34,0.834,0.421 μm,即随化铣温度增加,化铣后试样的表面粗糙度先增加后减小。

(6)摆放位置对TA15钛合金表面粗糙度的影响较小。

-

表 1 TA15的化学成分

Table 1 Chemical composition of TA15

元素 Ti Al V Mo Zr Si Fe C N H 其他 质量分数/% 87.87 6.46 1.7 1.38 2.16 0.024 0.096 0.016 0.016 0.002 <0.10 -

[1] 刘铭悦, 黄志全, 张习羽, 等. 非平衡磁控溅射CrTiAlN涂层的制备及空蚀性能研究 [J]. 表面技术, 2023, 52(10):367-375. LIU M Y, HUANG Z Q, ZHANG X Y, et al. Preparation and cavitation erosion resistance of CrTiAlN coatings by unbalanced magnetron sputtering [J]. Surface Technology, 2023, 52(10):367-375.

[2] 赵言医用合金材料磁流变超光滑抛光加工研究广州广东工业大学2021赵言. 医用合金材料磁流变超光滑抛光加工研究 [D]. 广州: 广东工业大学, 2021. ZHAO YStudy on magnetorheological ultra-smooth polishing of medical alloy materialsGuangzhouGuangdong University of Technology2021ZHAO Y. Study on magnetorheological ultra-smooth polishing of medical alloy materials [D]. Guangzhou: Guangdong University of Technology, 2021.

[3] 莫咏怡, 蔺小军, 田培森, 等. 不同刀具倾角下切削参数对TC4表面形貌影响规律研究 [J]. 工具技术, 2024, 58(3):43-48. MO Y Y, LIN X J, TIAN P S, et al. Study on influence of cutting parameters on surface morphology of TC4 at different tool angles [J]. Tool Engineering, 2024, 58(3):43-48.

[4] 王晓明, 韩江. TC4钛合金高速铣削表面粗糙度研究 [J]. 机械设计与制造, 2019(5):232-236,240. WANG X M, HAN J. Study on surface roughness of high speed milling of TC4 titanium alloy [J]. Machinery Design & Manufacture, 2019(5):232-236,240.

[5] 王慧, 李南奇, 赵国超, 等. 基于航空铸造钛合金Ti-6Al-4V高速铣削参数的表面质量及切削效率优化 [J]. 表面技术, 2022, 51(2):331-337,346. WANG H, LI N Q, ZHAO G C, et al. Optimization of surface quality and cutting efficiency for high-speed milling parameters of titanium alloy Ti-6Al-4V for aviation casting [J]. Surface Technology, 2022, 51(2):331-337,346.

[6] 储成龙, 刘长毅. 钛合金TC4高速铣削表面微观几何形貌仿真 [J]. 机械制造与自动化, 2010, 39(4):94-96. CHU C L, LIU C Y. Prediction of surface roughness of Ti alloy TC4 on high speed milling [J]. Machine Building & Automation, 2010, 39(4):94-96.

[7] 杨东, 贾天浩. TC4钛合金侧铣加工表面形貌分析及工艺参数优化 [J]. 海军航空大学学报, 2024, 39(1):131-138. YANG D, JIA T H. Surface morphology and parametric optimization of peripheral milling TC4 titanium alloy [J]. Journal of Naval Aviation University, 2024, 39(1):131-138.

[8] 邵勇, 孙树峰, 王萍萍, 等. 医用TC4钛合金激光-化学复合抛光及表面形貌演化 [J]. 中国表面工程, 2024, 37(2):227-237. SHAO Y, SUN S F, WANG P P, et al. Laser-chemical composite polishing and surface morphology evolution of medical TC4 titanium alloy [J]. China Surface Engineering, 2024, 37(2):227-237.

[9] 林翠, 梁静, 赵晴, 等. TA15钛合金腐蚀加工工艺研究 [J]. 材料工程, 2010, 38(8):51-55. LIN C, LIANG J, ZHAO Q, et al. Technology of corrosion processing of TA15 titanium alloy [J]. Journal of Materials Engineering, 2010, 38(8):51-55.

[10] 赵静, 周培培, 王晨羽. 钛合金TA15切削过程切削用量对表面粗糙度的影响 [J]. 机械工程与自动化, 2018(3):129-131. ZHAO J, ZHOU P P, WANG C Y. Effects on surface roughness of titanium alloy (TA15) cutting process caused by cutting amount [J]. Mechanical Engineering & Automation, 2018(3):129-131.

[11] 王明海, 王京刚, 郑耀辉, 等. 钛合金TA15高速铣削表面形貌及组织研究 [J]. 机床与液压, 2014, 42(23):71-74,78. WANG M H, WANG J G, ZHENG Y H, et al. Study on surface morphology and microstructure of titanium alloy TA15under high-speed milling [J]. Machine Tool & Hydraulics, 2014, 42(23):71-74,78.

[12] 王奔, 赵家兴, 张秀云, 等. 侧铣削参数对TC4钛合金表面粗糙度及材料去除率的影响 [J]. 工具技术, 2021, 55(12):9-12. WANG B, ZHAO J X, ZHANG X Y, et al. Effect of side milling parameters on surface roughness and material removal rate of TC4 titanium alloy [J]. Tool Engineering, 2021, 55(12):9-12.

[13] 伍娅, 乔虎, 曹岩. 砂带磨削钛合金表面粗糙度工艺参数的敏感性研究 [J]. 制造技术与机床, 2022(6):129-133. WU Y, QIAO H, CAO Y. Study on sensitivity of technical parameters of abrasive belt grinding of titanium alloy surface roughness [J]. Manufacturing Technology & Machine Tool, 2022(6):129-133.

[14] 李远博, 邵明辉, 李顺才, 等. 钛合金铣削表面粗糙度检测及多元预测模型研究 [J]. 现代制造工程, 2023(3):96-104. LI Y B, SHAO M H, LI S C, et al. Study on surface roughness measurement and multivariate prediction model of titanium alloy milling [J]. Modern Manufacturing Engineering, 2023(3):96-104.

[15] 王荣华, 汪振华. TC4钛合金铣削力及表面粗糙度分析 [J]. 工具技术, 2021, 55(5):30-33. WANG R H, WANG Z H. Analysis of milling force and surface roughness of TC4 titanium alloy [J]. Tool Engineering, 2021, 55(5):30-33.

[16] 蔡雨升, 韩洪智, 任德春, 等. 化学腐蚀工艺对激光选区熔化成形TC4钛合金表面粗糙度的影响 [J]. 材料研究学报, 2022, 36(6):435-442 CAI Y S, HAN H Z, REN D C, et al. The effect of chemical corrosion process on the surface roughness of TC4 titanium alloy formed by laser selective melting [J]. Journal of Materials Research 2022, 36(6):435-442.

下载:

下载: